|

Notes on using RG-174

Coaxial Cable

at Medium and Lower

HF Frequencies

by John Bryant

and Bill Bowers

Introduction

Over the past decade, I've slowly

become more aware of RG-174 coax, known in some

circles as "mini-coax" or even "micro-coax."

(diameter about .10 inch) For quite a while, I thought

that I knew two things about it: first, that there

was a great deal of signal loss involved, if you

chose to use RG-174; secondly, that it was very

expensive. In 2000, my friend Bill Bowers and I

undertook a project to prevent shield-born noise

and unwanted signals from riding coaxial lead-ins

into our receivers.

We adopted a scheme of

RF chokes and shield grounding similar to that recommended

by John Devoldere in his classic Low Band DXing,

Third Edition. The chokes were fabricated from ferrite

toroids wrapped with RG-174 coax. (Refer to our

article "Is

Your Lead-in Actually an Antenna?" published

by DXing.info and various other radio hobby publications

in 2001/2002.) During that project, I discovered

that RG-174 actually was relatively inexpensive;

it was available from various sources at around

$.20 USD per foot, with the price dropping for bulk

purchases.

Since that project in 2000, my

interests have drifted toward more mobile DXing,

often from somewhat remote DXpedition sites and

sometimes involving air travel to get to the site.

Quite naturally, I swiftly became disenchanted with

my long-term choices in coax, the ubiquitous RG-58AU

and RG-8X. These medium diameter coaxial cables

(diameters about .2 and .27 inch, respectively)

became both heavy and unruly when lengths got much

above 20 feet and yet they also seemed bulky and

stiff when used as short patch cords.

One day I happened to get an interior view of the

very expensive and highly regarded Ten Tec HF receiver,

the HF-340, and noticed numerous lengths of RG-174

interconnecting various sub-chassis; I also remembered

seeing 174 used as test leads for some very sophisticated

laboratory and medical equipment. Finally, the mental

light bulb lit and I began to wonder if the lossy

reputation of RG-174 wasn't as undeserved as its

supposed high cost. I checked several sources both

on and off Internet trying to find loss (or attenuation)

figures for RG-174 in the frequency range of my

own radio listening/DXing interests: 500 kHz to

6 MHz. I was unable to find any. The references

that gave any attenuation figures for 174 at all

tended to concentrate on VHF and UHF frequencies,

with possibly a token 10 MHz figure thrown in. Most

unsatisfactory!

I knew that Bill Bowers had spent

his career as a designer and manufacturer of specialized

coaxial cable, primarily for the oil industry and

that he had recently invested in very sophisticated,

laboratory grade, test equipment that could be used

to determine just exactly what the attenuation and

impedance characteristics were of RG-174 and similar

coax. I also was aware that Bill had written an

article for the long wave hobby publication Lowdown

on signal attenuation in coax at lower frequencies.

I contacted Bill and he was very interested and

agreed to run tests on 300-foot lengths of RG-174

and also of RG-58AU, the most commonly used coax

for lead-ins of listening antennas. Bill also supplied

an attenuation chart that did cover the losses for

these cables at frequencies down to 1 MHz. [John

Bryant]

Attenuation

Whether the additional losses

incurred by using RG-174 are a serious concern seems

to be dependant on both the lengths involved and

on your own level of concern about signal attenuation.

Bill's figures showed that the difference in attenuation

per hundred feet between the standard RG-58AU and

RG-174 varied from less than a quarter of a dB at

the low end of the broadcast band (500 kHz) to about

three-quarters of a dB at 6 MHz. I think that everyone

would agree that the differences between the two

are totally negligible for patch cords and short,

(ten to twenty feet), coax runs around the shack.

However, if you need lead-ins of over 100 feet or

more, the difference in losses at these frequencies

quickly passes 1 dB and heads south. There are also

concerns of physical robustness and ease of damage

of RG-174 coax in exterior applications, of course.

For myself, I'll continue to use RG-58AU for semi-permanent

exterior installations. However, for my next DXpedition

to a very remote site, I'm going to be using RG-174.

A coil of 100 feet of 174 makes a lump less than

the size of a soft ball and weighs almost nothing

Bill's findings are presented

on the next two pages. Following that, I'll address

sources for RG-174 and its requisite connectors

and techniques for attaching connectors to this

delicate cable.

Coaxial Cable

RG-174 & RG-58AU Characteristics

The cable data was

based on measurements using the HP-4192A Impedance

Analyzer. The cable tested was 300 feet of RG-174

& RG -58AU obtained from Jameco Electronics.

Measurements were made of the

cable impedance with the far end of the cable first

open circuited, (Zoc), and then short circuited,

(Zsc). The characteristic impedance is then calculated

by taking the square root of (Zoc) X (Zsc) .

The attenuation is measured directly

with the HP-4192A. Each end of the cable is terminated

with a 50 Ohm feed through terminator. The signal

generator output goes to a 50-Ohm Agilent "Power

Splitter". One output of the splitter goes

directly to Input "A" and the other to

one end of the cable. The other end of the 300 ft

cable is connected to Input "B". The HP-4192A

takes the difference between Terminal A & B

and displays the difference in db.

The RG-174, has only 88% shield

coverage, so I was concerned that there may have

been enough noise pickup to effect the measurements.

I repeated the measurements on a 100 ft length and

the results were very close to the 300 ft measurements.

Since the RG-58AU has braid coverage of 98%, there

was no need to repeat the 100 ft test.

The values of attenuation listed

are with the cable terminated in 50 Ohms. This is

the most common application and therefore the most

useful. The "true" attenuation of the

cable should be measured with the cable terminated

in ( Zo ). The value of ( Zo ), as listed above,

is only close to 50 Ohms at frequencies above 1

MHz.

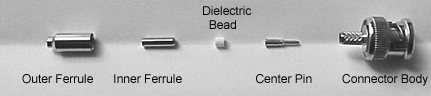

Assembling RG-174

BNC Connectors

If you have put

connectors on RG-8 or RG-58 "normal" coax,

you can put mechanically and electrically reliable

connectors on RG-174. You probably even have the

correct tools, since the only specialized tool necessary

is a good crimping tool for coax connectors. My

Radio Shack crimper (about $15.00) had both sizes

necessary for attaching connectors to RG-174: .068

inch diameter to crimp the center pin to the center

conductor of the coax (the same size crimp needed

for any BNC center pin) and .213 in. diameter to

crimp the outer ferrule. This latter is the same

size necessary for crimping RG-58 connectors, I

believe.

Here are the steps in assembling

a BNC connector on RG-174:

About the only difference

between attaching a BNC connector to RG-174 and

to larger coax is the existence of an inner ferrule

and insulating bead made out of dielectric material.

The outer braid of the coax (and some of the outer

jacket) ends up being trapped between the layers

of ferrules, while the inner conductor, with its

insulation in place, runs through both the inner

ferrule and the insulating bead. The inner conductor

itself is bare only within the center pin.

Slide the heat shrink tubing

and the outer ferrule onto the coax before beginning

to trim the coax end. Then, trim the end of the

RG-174 as follows:

· Slice the jacket (parallel

with the center conductor) for 3/4 inch, taking

care not to cut the braid beneath.

· Peal jacket back and trim 1/2 inch off

jacket.

· Grasp braid toward the end and push it

down the length of the center conductor. This causes

the braid to enlarge near the jacket and the basket

weave to open. Thread the insulated center conductor

out of the basket weave to separate the intact braid

sheath from the insulated center conductor.

· Remove 3/16 inch of insulation from the

center conductor to expose the inner conductor for

insertion in the center pin.

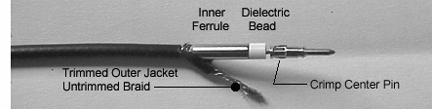

Next, slide the inner ferrule

and insulating bead onto the insulated inner conductor

and crimp the center pin on the bare 3/16 inch portion

of that conductor at the tip.

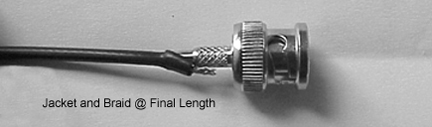

The connector body

is then put in place (you usually feel a slight

snap) and the braid is trimmed to about half its

original length:

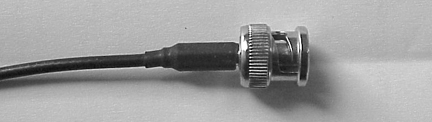

Finally, the outer

ferrule is slid down the coax to compress the tag-end

of the outer jacket and the braid between the two

ferrule bodies. The outer ferule is then crimped

firmly and the heat shrink tubing is put in place

over the outer ferrule and the final 1/4 inch or

so of the cable. I much prefer the heat shrink (available

from Eur-Am) with heat-activated adhesive on the

inner surface of the tubing. This product helps

to provide mechanical reinforcement to the cable-connector

joint.

Sources

To be honest, one

of the things that slowed my adoption of RG-174

was the fact that Radio Shack does not carry any

connectors for this small, delicate cable! However,

it appears that most parts houses do carry RG-174

cable; a simple Google search kicked up a number

of them. The prices varied between $.16 and $.20

USD per foot.

Please note, though, that all

of these are for the type of RG-174 that Bill tested:

RG-174 with 88% shield. The commonly available 174

is quite flexible and marvelous to use. Its flexibility

makes it ideal for making those RF antenna lead-in

chokes that Bill and I built three years ago. The

flexibility and size make it ideal for short runs

and patch cords around the shack, too. For those

of you who might be worried about introducing ambient

shack noise into your system due to the 88% shielding,

I replaced all of my RG-58AU patch cords with the

88% shielded RG-174 and noted no increase in noise,

despite running two laptop computers and a radio

with a noisy display all in close proximity to my

main communications receiver. Your mileage may vary

:>) I am aware of the fact that a less flexible,

but 100% shielded RG-174 exists. However, to this

point, I've found no retail source for this cable.

Sources of RG-174 cable:

Jameco

All-Electronics

Finding standard connectors with the special sleeves

and ferrules to accept the slender RG-174 is bit

more difficult. To date, I have used only three

sources (whose prices vary widely, by the way):

Nebraska

Surplus

L-Com

Connectivity

Eur-Am

Frankly, I prefer Eur-Am's connector and I REALLY

appreciate the fact that they also can supply heat-shrink

tubing with a coating of heat-activated mastic on

the interior of the tubing. I consider using this

tubing to cover the joint between the connector

and the cable as key to creating a long-lived trouble-free

cable.

Published on DXing.info

on June 25, 2003

|